IoT (World wide web of Factors) devices and Sophisticated analytics are used to observe machine overall health in true time, in a approach known as predictive servicing.

Once you're wanting to go, the subsequent action is usually to determine your use circumstances. These are typically the particular problems or opportunities where you Feel AI can assist.Try to remember, AI isn't a silver bullet that will address all your difficulties. It's a Instrument that is very good at certain things, like discovering patterns in info, producing predictions, and optimizing processes.

With this integration, production options are optimized with serious time details from the store ground to stop bottlenecks and increase Over-all throughput.

Learn how evolving tariffs in 2025 will effect the global import and export of CNC machines and parts. Find out critical trade shifts, cost implications, And just how U.S. CNC outlets can adapt to switching tariff insurance policies.

MultiCam's tables are created utilizing precision laser calibration equipment and major metal frames, So guaranteeing accuracy, longevity and steadiness through cutting procedures. Many of MultiCam's styles even appear preloaded with materials databases of saved options like feed amount and pierce delay, eliminating the necessity to reprogram them each time different materials are used.

Consistency and Repeatability: These machines present regular and repeatable final results, crucial for top-volume production operates.

When selecting the best measurement CNC lathe, youll choose to think about the aspect dimensions O.D. that you will be producing. Equally as the axis motion, live tooling, and quite a few tooling positions travel the complexity of parts that can be made, the bar ability outer diameter sizing establishes the scale parts. Bar feeders press the stock with the collets for production runs.

CNC machining can achieve new heights by integrating AI and machine Discovering, providing your Group an fascinating opportunity to innovate and expand together with the technology.

Among the greatest advantages of AI in CNC machining is predictive upkeep. Usually, servicing is scheduled at standard intervals, if the machine Here wants it or not. But with AI, we will predict when a machine is likely to are unsuccessful, based upon its running problems and historical information. This means we can easily take care of things ahead of it breaks, lowering downtime and saving money.Sensors on the machinery obtain data on such things as temperature, vibration, and sound. This info is then fed into an AI algorithm that appears for patterns and anomalies.

Programming: The CNC lathe is programmed with a specific list of instructions (G-code) that dictate the movements from the cutting Device along with the rotation with the workpiece. This code is often created by CAD/CAM program based on the desired design.

3 mm was artificially induced by machining with the identical materials before the data amassing experiment. Two techniques ended up used in an effort to examine the data and create the machine learning system (MLP), in a previous Examination. The collected details established was tested without any former cure, with an ideal linear associative memory (OLAM) neural network, and the effects showed 65% accurate solutions in predicting tool have on, thinking of 3/four of the information established for training and 1/four for validating. For the next method, statistical details mining approaches (DMM) and information-pushed approaches (DDM), referred to as a self-Arranging deep Discovering method, ended up employed in order to increase the good results ratio from the product. The two DMM and DDM used alongside with the MLP OLAM neural community showed an increase in hitting the best answers to 93.eight%. This product could be practical in machine checking employing Industry four.0 ideas, where by one of several key difficulties in machining components is getting the right second for your Software transform.

AI also allows real-time checking and control of CNC machines. Because of this we can control what's taking place constantly, and make adjustments over the fly. For example, if a Resource is wearing down, the system can compensate by altering the machine's options.This is completed working with a little something referred to as a electronic twin. It is really in essence a virtual replica with the Actual physical machine, complete with all its sensors and information points.

The muse of any State-of-the-art CNC operation lies in comprehending the fundamental areas of CNC milling machines. These machines have transformed industries, providing unparalleled precision and efficiency. In advance of diving into the intricacies, Allow’s explore the fundamentals of CNC milling machines.

This paper evaluations the techniques of synthetic neural community (ANN) on machining general performance. ANN regarded as A prosperous method of modelling the machining process for predicting overall performance measures by means of the development of an authority system. An authority system is undoubtedly an interactive intelligence software with a specialist-like effectiveness in fixing a certain form of dilemma employing expertise base, inference engine and user interface.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Jenna Von Oy Then & Now!

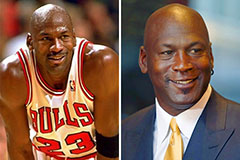

Jenna Von Oy Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now!